What are the Commonly Used Circuit Protection Components?

Introduction to Circuit Protection

| Topics covered in this article: |

| Ⅰ. What is the meaning of circuit protection? |

| Ⅱ. Lightning protection devices |

| Ⅲ. Overvoltage devices |

| Ⅳ. Overcurrent devices |

| Ⅴ. Electrostatic components |

When overvoltage, overcurrent, surges, and other events occur, electronic circuits are readily damaged. Electronic circuit goods are becoming more diversified and intricate as technology advances, and circuit protection has become increasingly critical. From simple glass tube fuses to more types and better protection performance, circuit protection components have evolved.

Ⅰ. What is the meaning of circuit protection?

Overvoltage and overcurrent protection are becoming increasingly vital in all types of electronic equipment, so let's have a look at what circuit protection entails today:

(1) As the integration of circuit boards becomes more advanced, the price of the board rises as well, necessitating increased protection.

(2) The operating voltage of semiconductor devices is decreasing, and the goal of circuit protection is to decrease energy loss, reduce heat generation, and extend service life.

(3) In-vehicle equipment: Because the usage environment is harsher than for common electronic items, the driving circumstances of the automobile change, resulting in a large instantaneous peak voltage when the car is started. As a result, overvoltage protection components are commonly utilized in power adapters to support these electronic devices' goods.

(4) Lightning and surge protection are required for communication equipment and communication locations. The usage of overvoltage and overcurrent protection components in this equipment becomes critical. They're essential for ensuring user privacy and normal communication.

(5) The majority of electronic product failures are caused by overvoltage or circuit abnormalities in the electronic equipment's circuit. The protection of electronic circuits has become increasingly critical as our expectations for the quality of electronic equipment have risen.

So, given the importance of circuit protection. what are the most widely utilized circuit protection components? I'll introduce you to a few today.

Ⅱ. Lightning protection devices

1. Ceramic gas discharge tube:

The ceramic gas discharge tube is the most extensively used lightning protection device. The ceramic gas discharge tube is the most widely used lightning protection device because it is the most widely used lightning protection device whether it is for the lightning protection of the DC power supply or the lightning protection of various signals. The tube can provide adequate protection.

Figure. 1

The huge flux, small interstage capacitance, strong insulation resistance, and a wide range of possible breakdown voltages are its most notable features.

2. Semiconductor discharge tube:

The thyristor principle is used to create a semiconductor discharge tube, which is an overvoltage protection device. The device's conduction and discharge are triggered by the PN junction's breakdown current, and it can flow a huge surge current or pulse current. Overvoltage protection is defined by the range of its breakdown voltage.

Figure. 2

The solid discharge tube can be directly attached to both ends of the protected circuit when it is employed. Precision conduction, fast response (response time ns level), great surge absorption capacity, bidirectional symmetry, and high dependability are all features of this device.

3. Glass discharge tube:

At the turn of the twentieth century, the glass discharge tube (also known as a forceful discharge tube or a lightning protection tube) was introduced as a novel lightning protection technology. High insulation resistance (108), exceptionally small inter-capacitance (0.8pF), big discharge current (up to 3 kA), bidirectional symmetry, fast response (no hysteresis of impact breakdown), steady and reliable performance, the low voltage after turn-on,

Figure. 3

Furthermore, it has a high DC breakdown voltage (up to 5000V), a small size, and a long life. The DC breakdown voltage has a considerable dispersion (20%), which is a drawback.

Ⅲ. Overvoltage devices

1. Varistor:

One of the most often used voltage limiting devices is varistors. When an overvoltage arises between the two poles of the varistor, the varistor's nonlinear features allow it to clamp the voltage to a relatively stable voltage value, ensuring the succeeding circuit's protection.

Figure. 4

The varistor has a response time of ns, which is faster than the air discharge tube but slower than the TVS tube. In general, the overvoltage protection utilized in electronic circuits can meet the criteria in terms of response time. The varistor's junction capacitance is typically on the order of several hundred to several thousand pF. It should not be used directly to safeguard high-frequency signal lines in many circumstances. The huge junction capacitance will increase leakage when utilized to protect AC circuits. When designing a protective circuit, the current must be taken into account completely. The varistor has a higher flow capacity than the gas discharge tube, although it is still smaller.

2. The role of the chip varistor:

Chip varistors are mainly used to protect components and circuits from ESD generated in power supply, control, and signal lines.

Figure. 5

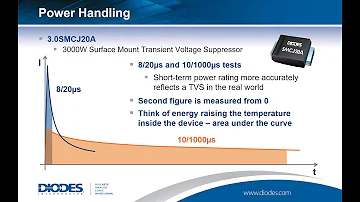

3. TVS diode:

TVS diodes, or transient suppressor diodes, are frequently utilized in the secondary protection of semiconductors and sensitive equipment. It is primarily used as secondary protection following the ceramic gas discharge tube, while some users utilize it as the primary protection of the product.

Figure. 6

It has a fast response time (ps level), is compact, has a large pulse power, and has a low clamping voltage. Its 10/1000s wave pulse power spans from 400W to 30KW, with peak pulse currents ranging from 0.52A to 544A. Its breakdown voltage ranges from 6.8V to 550V, making it suitable for circuits with varying voltages.

Ⅳ. Overcurrent devices

1. Self-recovery fuse:

Fuse for self-recovery PPTC is an overcurrent electronic protection element that is made using a specific technique that involves adding conductive particle materials and vulcanizing a high molecular organic polymer under high pressure, high temperature, and vulcanization reaction. A self-recovery fuse (PPTC: polymer self-recovery fuse) is a polymer thermistor with a positive temperature coefficient that is used for overcurrent protection and can be used in place of a current fuse.

Figure. 7

When the circuit is in good operating order, the resistance is quite low (the voltage drop is very small). When the circuit's temperature rises owing to overcurrent, the resistance value climbs dramatically by several orders of magnitude, lowering the circuit's current below the safe level. As a result, the circuits below are protected, and the resistance will automatically recover to a low value after the overcurrent has passed.

Ⅴ. Electrostatic components

1. ESD electrostatic discharge diode:

The ESD Electrostatic Discharge Diode is an anti-static component that protects I/O ports in high-speed data transmission applications against overvoltage. Electrostatic diodes, or ESD diodes, are used to safeguard sensitive circuits in electronic equipment from ESD (Electrostatic Discharge).

Figure. 8

Provides extremely low capacitance, good Transmission Line Pulse (TLP) testing, and IEC6100-4-2 testing capabilities, particularly after multi-sample counts of up to 1000, enhancing the protection of sensitive electronic components.

2. The role of inductance:

I suppose that everyone is aware of the electromagnetic link. If there is a current running through the inductance at the beginning of the circuit, when everything is still unstable, an induced current in the opposite direction of the current will be formed (Faraday's law of electromagnetic induction). , after the circuit has been running for a period of time, everything is stable, the current has not changed, and electromagnetic induction will not generate current, it will be stable at this time, and there will be no sudden changes, thus ensuring the circuit safety, similar to a waterwheel, which turns slowly at first due to resistance, and then gradually becomes more peaceful.

Figure. 9

3. The role of magnetic beads:

Magnetic beads have a high resistivity and permeability, which is equal to series resistance and inductance connection, although the resistance and inductance values alter with frequency. It has stronger high-frequency filtering qualities than typical inductors, and because it is resistive at high frequencies, it can sustain a high impedance across a wide frequency range, enhancing FM filtering effects. It's a feature found on Ethernet chips.

Figure. 10

1. What is an overcurrent protector?

The overvoltage protector can release the excessive voltage to the ground through the protector. But a protector that shunts the overcurrent to where it goes.

2. What protections are in the circuit?

Three-phase short-circuit protection, two-phase short-circuit protection, overload protection, composite voltage overcurrent protection, overvoltage protection, undervoltage protection, zero sequence protection, differential protection, unbalance protection, etc.

3. What are the circuit protection devices?

The circuit protection device has 1. fuse - overcurrent protection, which can only be used once. 2. Self-recovery fuse - overcurrent protection, can be reset and reused 3. Metal oxide varistor, surge absorber. 4. TVS surge current limiter avoids damage to gas discharge tube circuit breaker caused by surge current. 5. The overcurrent actuated switch accumulates the thermal relay. 6. Overcurrent actuated switch ground leakage protection socket (GFCI) or RCD

Discovering New and Advanced Methodology for Determining the Dynamic Characterization of Wide Bandgap DevicesSaumitra Jagdale15 March 20242415

Discovering New and Advanced Methodology for Determining the Dynamic Characterization of Wide Bandgap DevicesSaumitra Jagdale15 March 20242415For a long era, silicon has stood out as the primary material for fabricating electronic devices due to its affordability, moderate efficiency, and performance capabilities. Despite its widespread use, silicon faces several limitations that render it unsuitable for applications involving high power and elevated temperatures. As technological advancements continue and the industry demands enhanced efficiency from devices, these limitations become increasingly vivid. In the quest for electronic devices that are more potent, efficient, and compact, wide bandgap materials are emerging as a dominant player. Their superiority over silicon in crucial aspects such as efficiency, higher junction temperatures, power density, thinner drift regions, and faster switching speeds positions them as the preferred materials for the future of power electronics.

Read More A Comprehensive Guide to FPGA Development BoardsUTMEL11 September 202511673

A Comprehensive Guide to FPGA Development BoardsUTMEL11 September 202511673This comprehensive guide will take you on a journey through the fascinating world of FPGA development boards. We’ll explore what they are, how they differ from microcontrollers, and most importantly, how to choose the perfect board for your needs. Whether you’re a seasoned engineer or a curious hobbyist, prepare to unlock new possibilities in hardware design and accelerate your projects. We’ll cover everything from budget-friendly options to specialized boards for image processing, delve into popular learning paths, and even provide insights into essential software like Vivado. By the end of this article, you’ll have a clear roadmap to navigate the FPGA landscape and make informed decisions for your next groundbreaking endeavor.

Read More Applications of FPGAs in Artificial Intelligence: A Comprehensive GuideUTMEL29 August 20252947

Applications of FPGAs in Artificial Intelligence: A Comprehensive GuideUTMEL29 August 20252947This comprehensive guide explores FPGAs as powerful AI accelerators that offer distinct advantages over traditional GPUs and CPUs. FPGAs provide reconfigurable hardware that can be customized for specific AI workloads, delivering superior energy efficiency, ultra-low latency, and deterministic performance—particularly valuable for edge AI applications. While GPUs excel at parallel processing for training, FPGAs shine in inference tasks through their adaptability and power optimization. The document covers practical implementation challenges, including development complexity and resource constraints, while highlighting solutions like High-Level Synthesis tools and vendor-specific AI development suites from Intel and AMD/Xilinx. Real-world applications span telecommunications, healthcare, autonomous vehicles, and financial services, demonstrating FPGAs' versatility in mission-critical systems requiring real-time processing and minimal power consumption.

Read More 800G Optical Transceivers: The Guide for AI Data CentersUTMEL24 December 20252094

800G Optical Transceivers: The Guide for AI Data CentersUTMEL24 December 20252094The complete guide to 800G Optical Transceiver standards (QSFP-DD vs. OSFP). Overcome supply shortages and scale your AI data center with Utmel Electronic.

Read More Xilinx FPGAs: From Getting Started to Advanced Application DevelopmentUTMEL09 September 20253750

Xilinx FPGAs: From Getting Started to Advanced Application DevelopmentUTMEL09 September 20253750This guide is your comprehensive roadmap to understanding and mastering the world of Xilinx FPGA technology. From selecting your first board to deploying advanced AI applications, we'll cover everything you need to know to unlock the potential of these remarkable devices. The global FPGA market is on a significant growth trajectory, expected to expand from USD 8.37 billion in 2025 to USD 17.53 billion by 2035. This surge is fueled by the relentless demand for high-performance, adaptable computing in everything from 5G networks and data centers to autonomous vehicles and the Internet of Things (IoT). This guide will walk you through the key concepts, tools, and products in the Xilinx ecosystem, ensuring you're well-equipped to be a part of this technological revolution.

Read More

Subscribe to Utmel !

![HCS201/P]() HCS201/P

HCS201/PMicrochip Technology

![AT88SC0404CA-TH]() AT88SC0404CA-TH

AT88SC0404CA-THMicrochip Technology

![DLPC300ZVB]() DLPC300ZVB

DLPC300ZVBTexas Instruments

![SI8235BB-D-IS1]() SI8235BB-D-IS1

SI8235BB-D-IS1Silicon Labs

![ACPL-P343-560E]() ACPL-P343-560E

ACPL-P343-560EBroadcom Limited

![ADUM3221ARZ-RL7]() ADUM3221ARZ-RL7

ADUM3221ARZ-RL7Analog Devices Inc.

![NBSG16BAR2]() NBSG16BAR2

NBSG16BAR2ON Semiconductor

![TDA7803A-ZSX]() TDA7803A-ZSX

TDA7803A-ZSXSTMicroelectronics

![HCS362-I/ST]() HCS362-I/ST

HCS362-I/STMicrochip Technology

![DLPA3000CPFD]() DLPA3000CPFD

DLPA3000CPFDTexas Instruments